Lean Machines For World Class Manufacturing And Maintenance Pdf

For many companies it is a suitable long term goal.

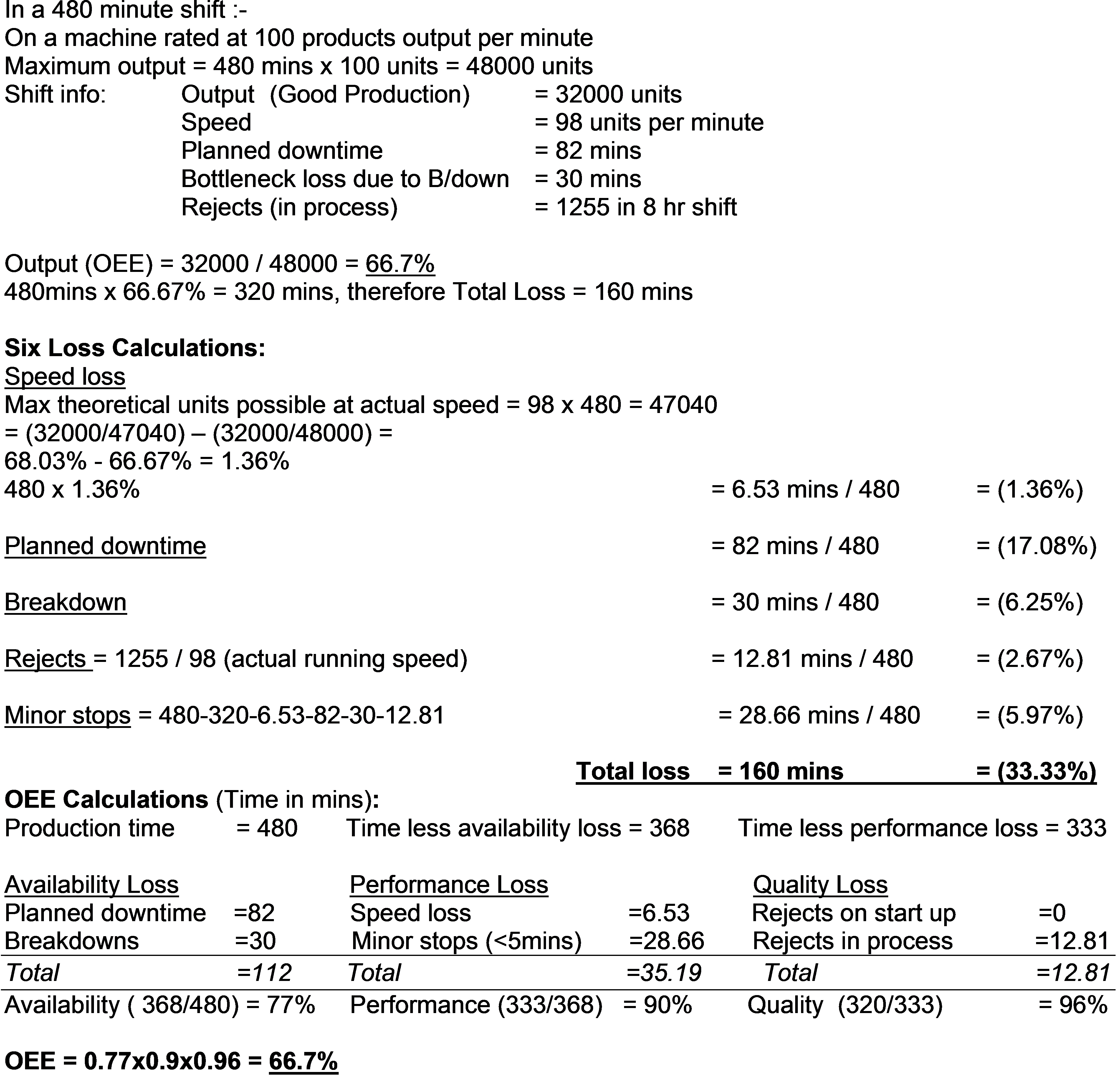

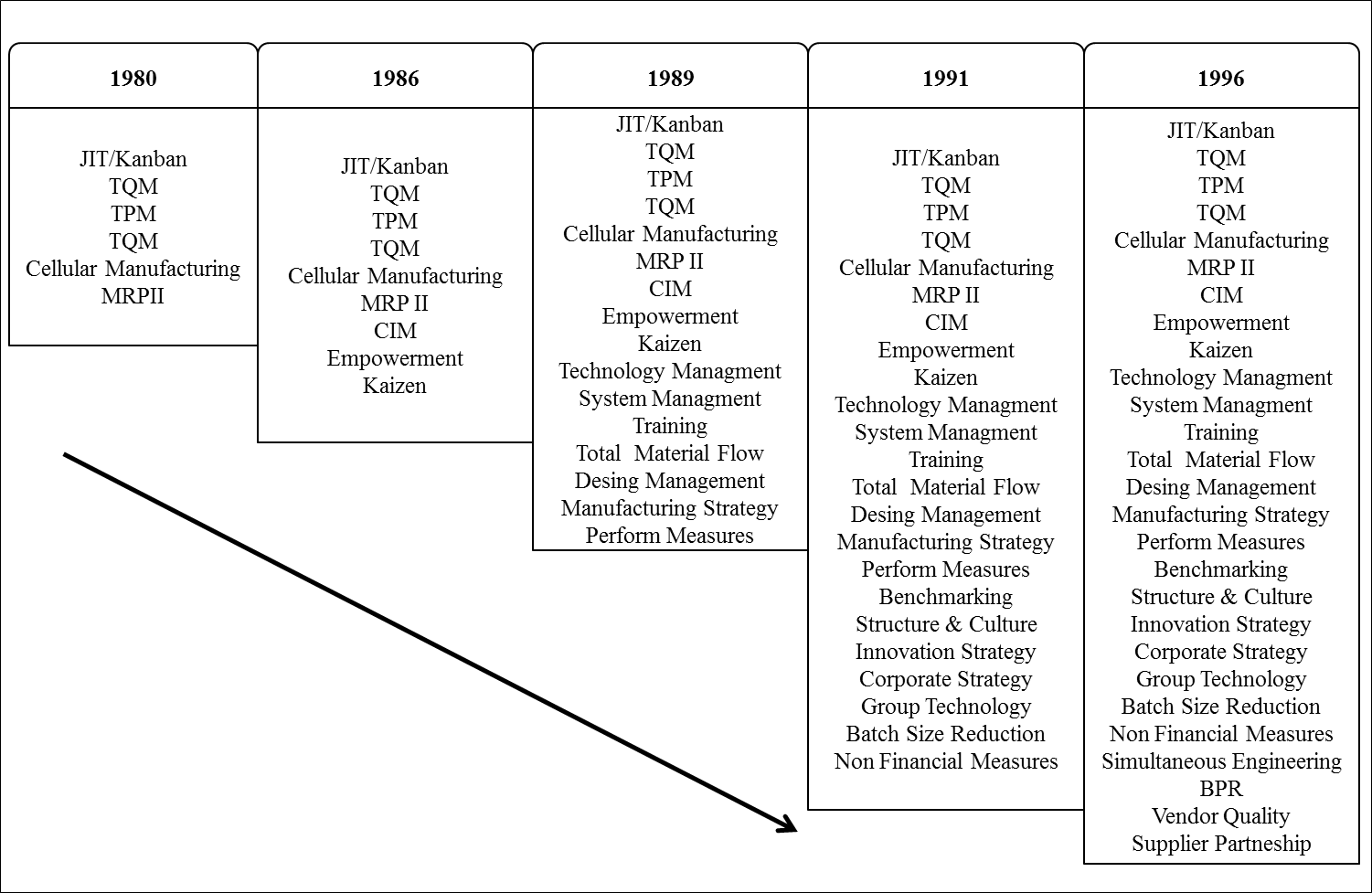

Lean machines for world class manufacturing and maintenance pdf. 181 introduction to lean manufacturing lean manufacturing or lean production are reasonably new terms that can be traced to jim womack daniel jones and daniel roos book the machine that changed the world 1991. Refers to the difference between equipment design speed and the actual operating speed. An oee score of 100 is perfect production. Williamsonthis updated edition launches the next level of world class simplicity for modern manufacturing and maintenance.

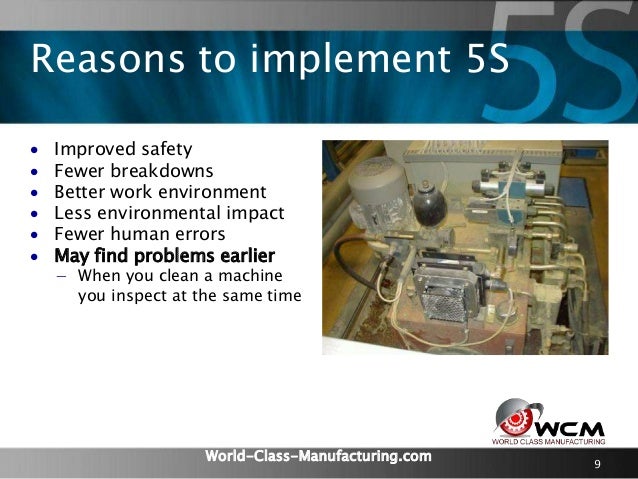

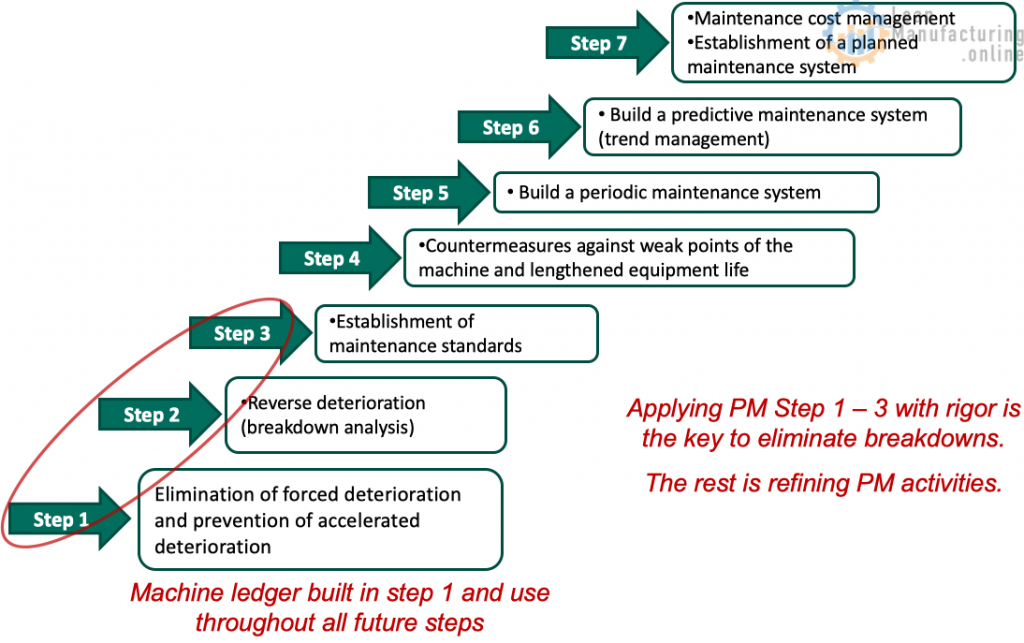

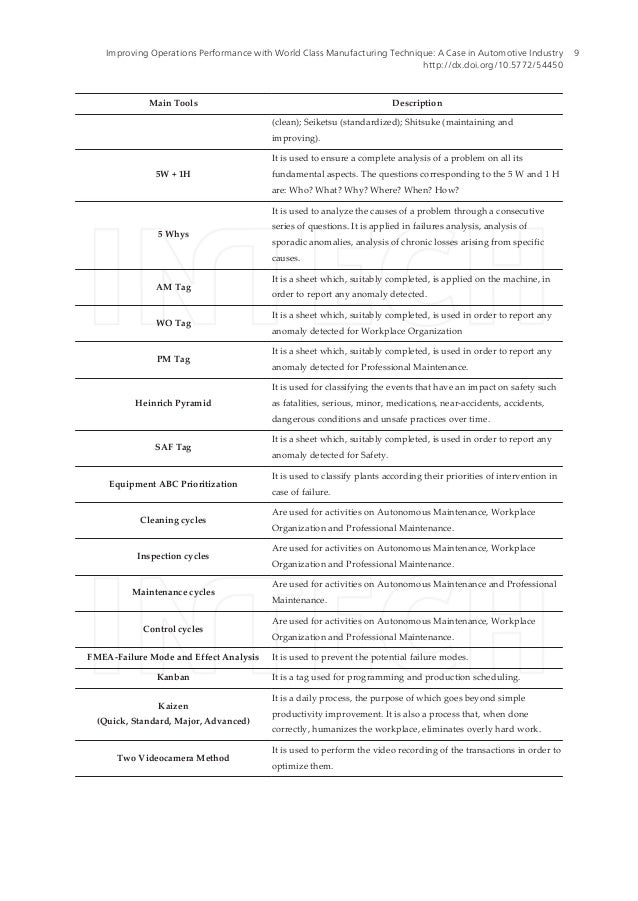

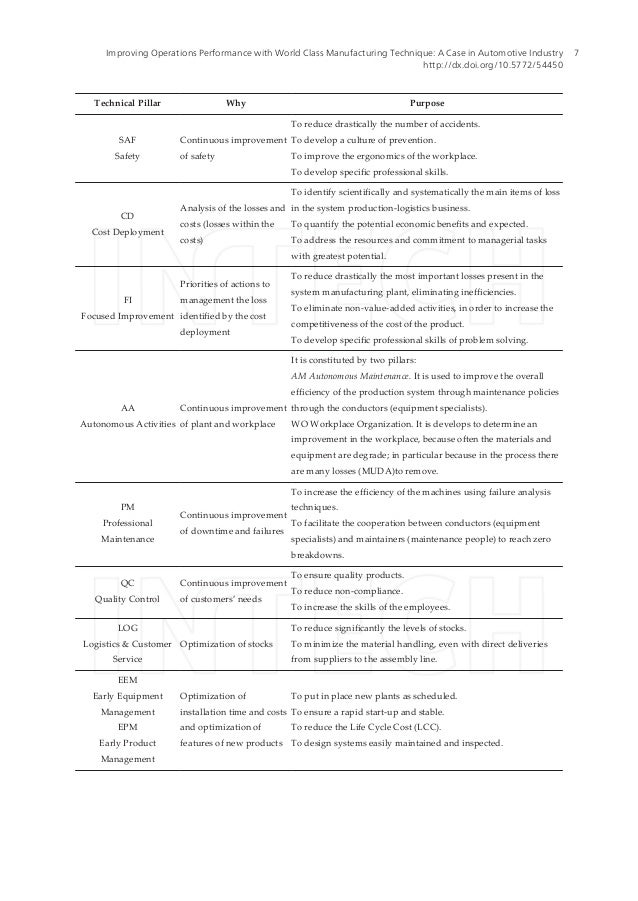

The six big losses are extremely important because they are nearly universal in application for discrete manufacturing and they. Tpm total productive maintenance is a holistic approach to equipment maintenance that strives to achieve perfect production. The measurement ive used for the last 15 years is based on the results of the manufacturing excellence audit mea process as detailed in the appendix of my book 12 principles of manufacturing excellencea lean leaders guide to achieving and sustaining excellence 2 nd. In the book the authors examined the manufacturing activities exemplified by the toyota production system.

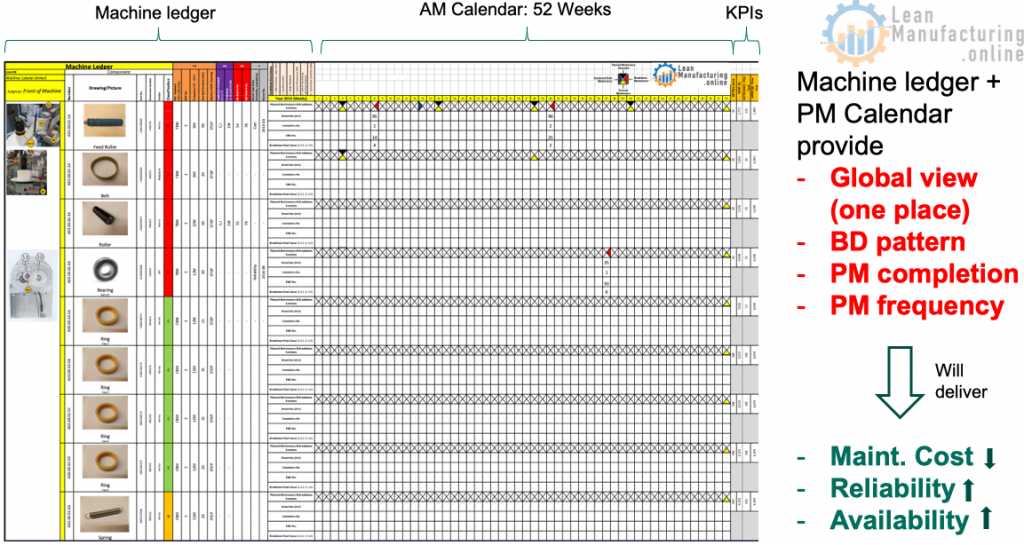

Manufacturing only good parts as fast as possible with no stop time. 7 observed that to qualify as world class a plant had to demonstrate outstanding performance on both productivity and quality meas ures. Lean maintenance tries to avoid wasted effort in maintenance by scheduling condition based maintenance test or inspect each machine then schedule maintenance when it begins to show signs of wear. Instead oliver et al.

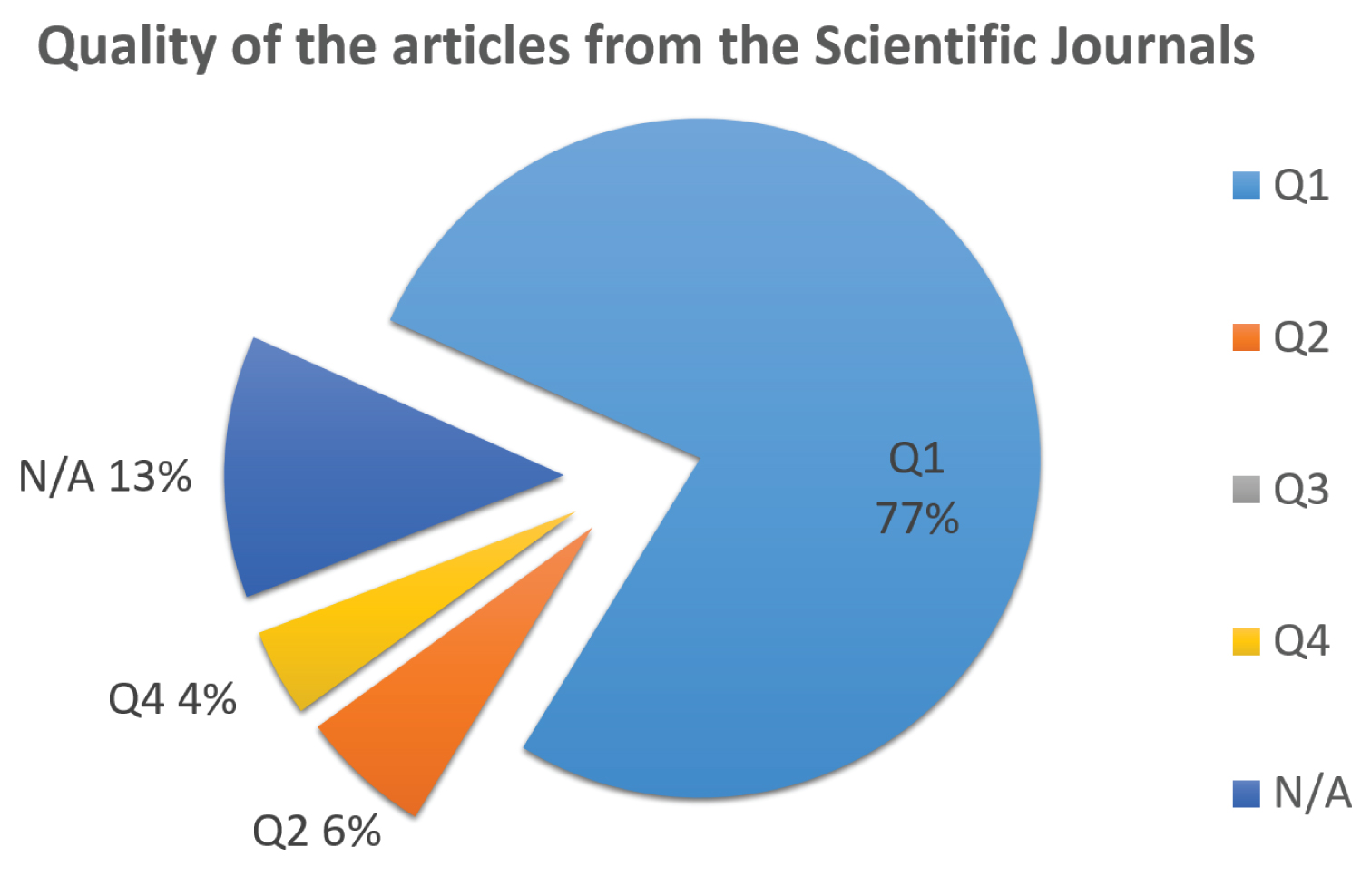

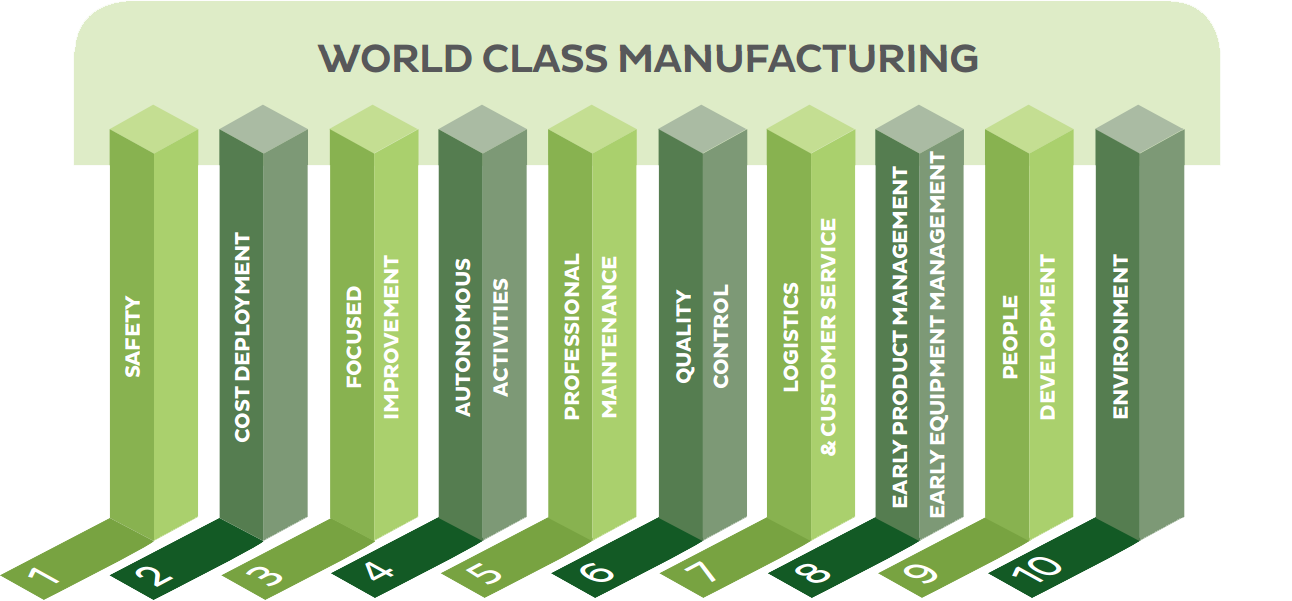

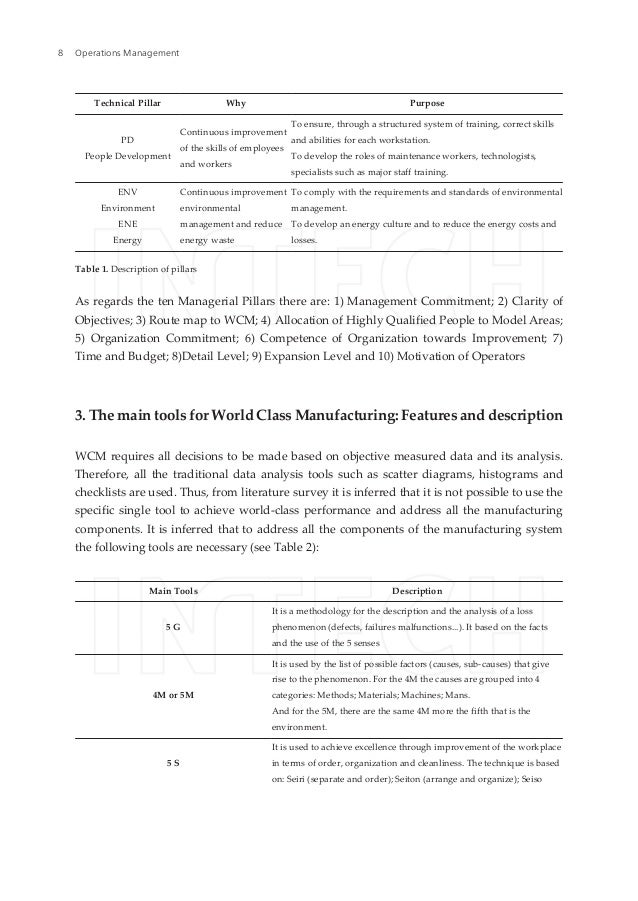

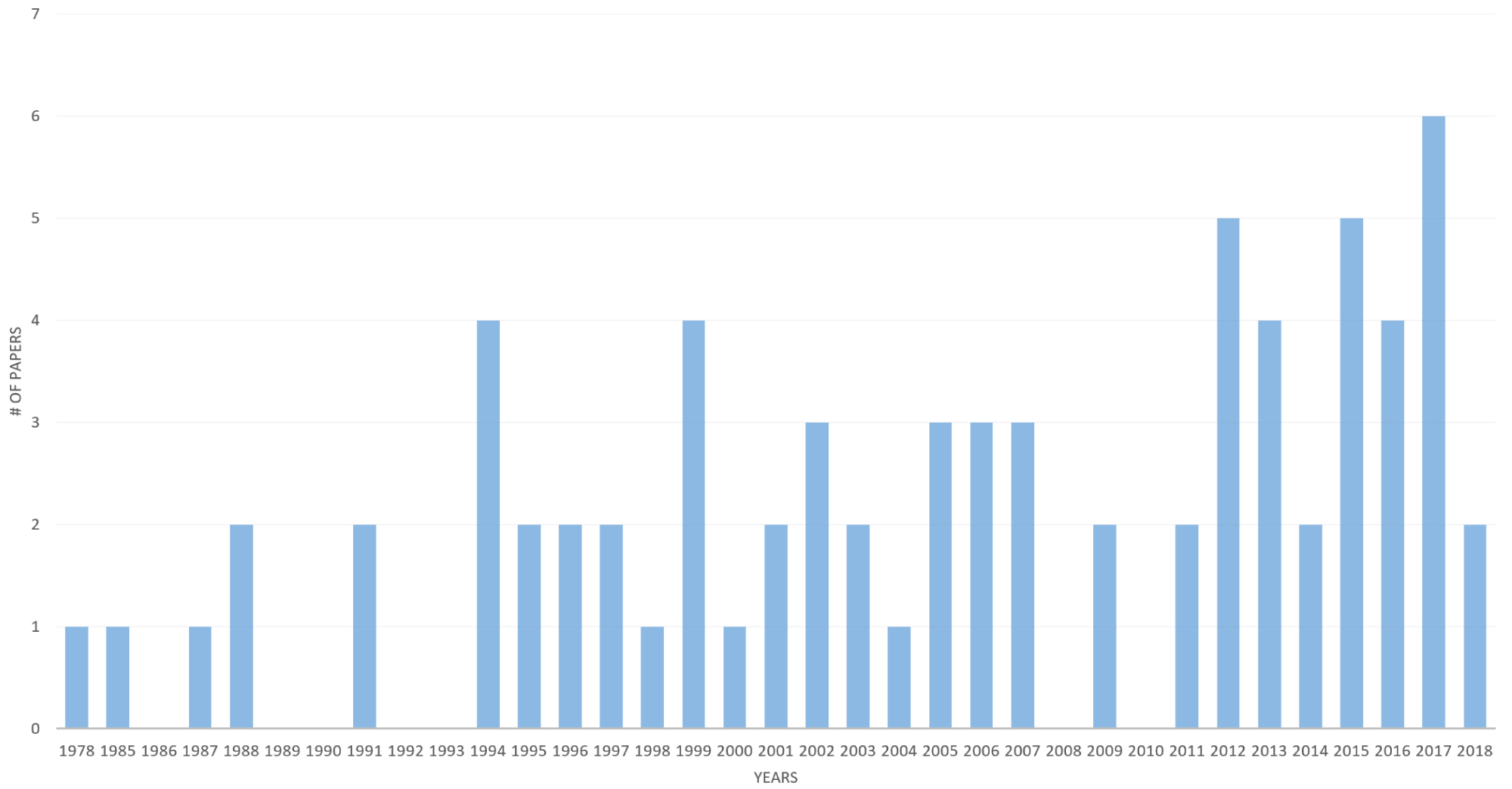

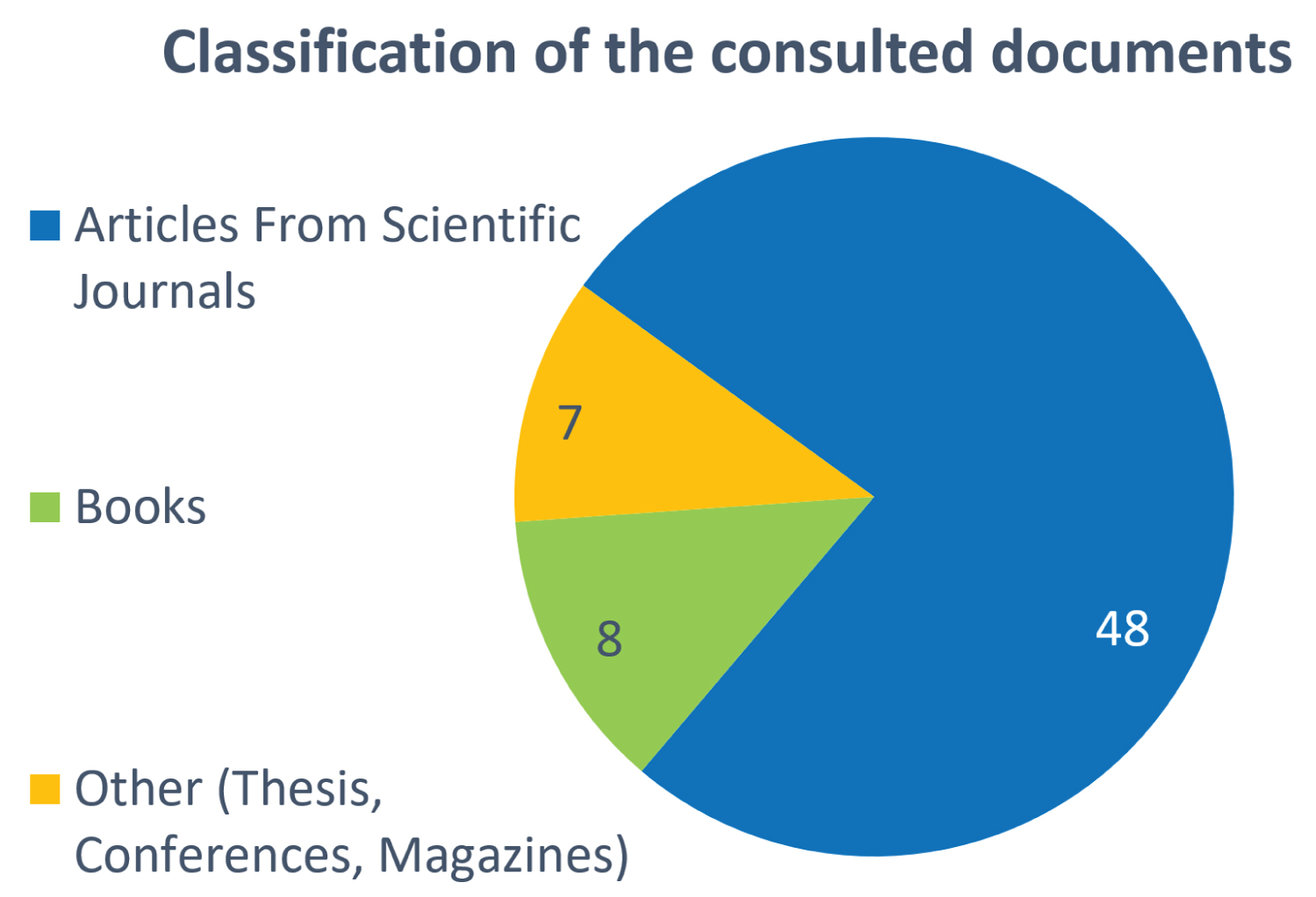

An oee score of 85 is considered world class for discrete manufacturers. An oee score of 85 is world class for discrete manufacturers. This approach can reduce the waste of storing an excessive inventory of replacement parts for too long as well as the waste of time to procure out. Summing up we can state that the term world class manufacturing wcm means the pursuance of best practices in manufacturing.

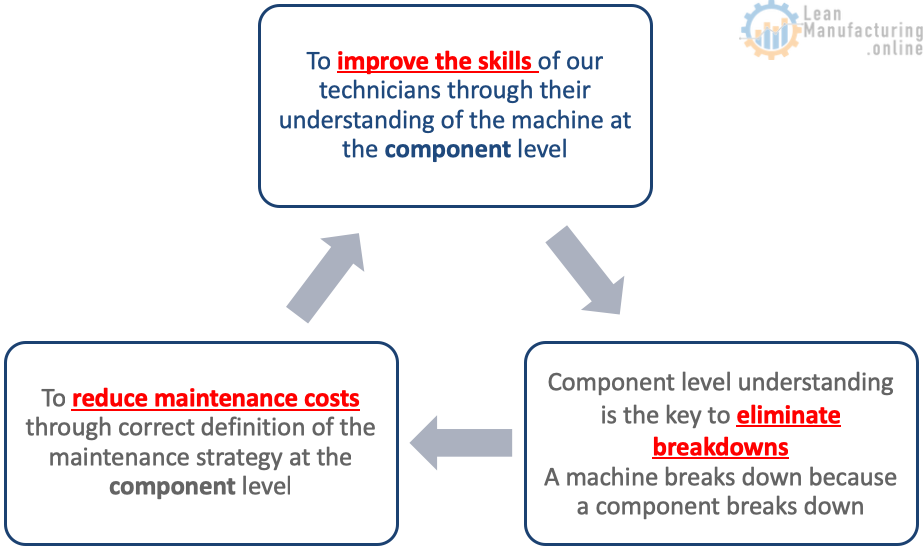

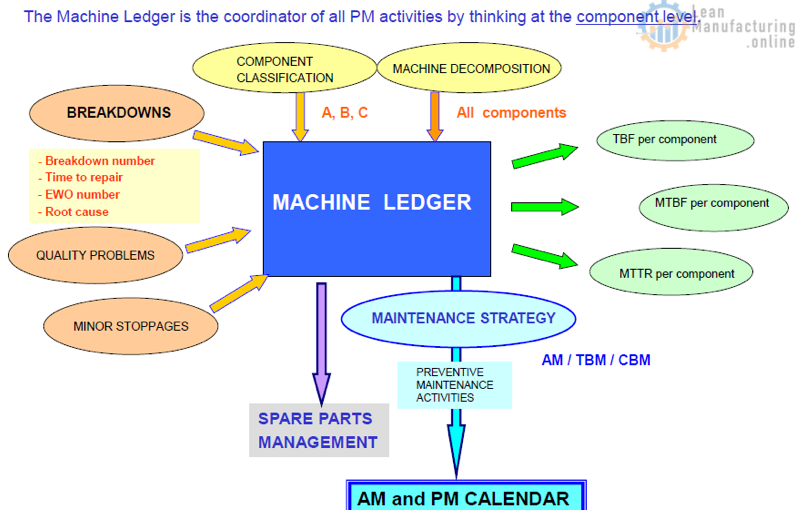

Plan it well with clear deliverables x maintenance cost oee improvement one machine of 2000 components. 2 technicians 100 for 10 12 weeks. We have collected and explained proven methods for simplifying the interactions between people and machines.